"No matter how one feels about the outside cover of a magazine, George E. Valentine's The Inside Story of the Outside Cover will be a surprise. If you think that the production of four color engraving plates is a simple matter, you will do some quick revising of your thinking. If you have a certain admiration for the technical skill that goes into such work, that admiration is likely to be heightened by Mr. Valentine's step by step story of the creation of a four color magazine cover. Aside from the story it tells, Mr. Valentine's film is a real technical achievement because of the working conditions under which most of the shots were of necessity filmed. His peak sequence — a proof-press run analyzed in slow motion — was achieved by mounting the camera directly on the moving press. When you can do that, you're good." Movie Makers, Dec. 1947, 539.

"David W. Kean has made a simple expository film of a two-man gold mining outfit. But in it he has kept the human touch. A well written narrative supplements the pictured material in explaining the various operations that ultimately produce man's most valued metal. Interior and underground scenes are competently handled and surmount what must have been difficult lighting problems. The production of King of Metals is aptly in scale with the extent of its subject matter." Movie Makers, Dec. 1950, 468.

“Ruhi Su ve Rahmi Saltuk türküleri eşliğinde yoksulluk ve emek sömürüsünü ve mücadeleyi, direnişi farklı, ilginç bir kurgu ile anlatmış. 13 dakikalık 1969 yılı koşullarını düşünerek izlemek gerekiyor.” Sinematek.tv: http://sinematek.tv/kordugum-1969-2/ (15 Oct 2019).

“Accompanied by Ruhi Su and Rahmi Saltuk’s folk songs, the film tells the story of poverty, struggle, and resistance in a different way, with an interesting montage. This 13-minute-long film requires audiences to acknowledge the contexts of the year 1969 in viewing.” Sinematek.tv: http://sinematek.tv/kordugum-1969-2/ (15 Oct 2019).

"This fascinating film records the steelworks at Irlam in Salford, which became part of the Lancashire Steel Corporation in 1930. We see the loading yard, the mine arch plant and foundry, where men carry out their hazardous work in the heat and smoke from the molten steel. Then a respite - a look into the drawing office and template room, before returning to the factory floor and heavy machinery." (BFI Player)

"Kendall T. Greenwood has told an interesting and uniformly attractive story of one of America's great integrated industries in Let Your Body Breathe. From the original Goodall Company plant in Sanford, Maine, to the elaborate retailing methods of the present day, the film presents a clear cut picture of Palm Beach cloth and its part in the modern pattern of warm weather living. Designed primarily for use within the trade, Let Your Body Breathe shows the retailer all the important points in the manufacture of this fabric, its tailoring by the parent company into suits and sportswear and the continued control over the product, even to such details as proper laundering or cleaning. Mr. Greenwood's camera work is crisp, his editing incisive, while the narrative contributes judiciously to an able industrial record." Movie Makers, Dec. 1941, 568.

"Documentary about the process of digging for worms during low tide, washing and packaging them in rockweed, and shipping them by rail and truck. The film uses intertitles and shows the tools used for worming as well as snow scenes of the Maine Bait Company among other businesses." oldfilm.org

"doc. didattico"/educational film

"To make clear the entire course of sanitary milk production, from pasture to home table, the State of Illinois Department of Public Health, in Springfield, Ill., is using a two reel, 16mm. film entitled Milk, Its Production and Pasteurization. Produced by Dr. A. C. Baxter, ACL, assistant director of public health, the film presents in interesting and informative sequences the modern technique of dairy farming and the relation of the department to it." Movie Makers, June 1934, 262.

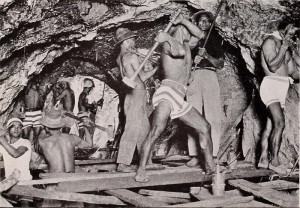

"An outstanding example of industrial record filming is Mining Chrome Ore in New Caledonia, by Enoch Perkins, ACL. Probably no amateur film ever was made under more unfavorable conditions and with as little opportunity to secure special equipment to meet them. Yet the photographic quality of this film is very high and it stands as a tribute to Mr. Perkins's ability to overcome obstacles. A large part of the picture was made in a mine where the atmosphere was so charged with moisture that it was necessary to stop and wipe the lens dry every few minutes. Although lighting was a tremendous task and often cables over a thousand feet long were required, the mine scenes are accurately exposed and well photographed. The picture gives a complete record of mining ore from the solid wall of the tunnels to the loaded freighter. It was filmed from an engineer's point of view and for the specific purpose of record; however, smooth continuity and editing maintain audience interest." Movie Makers, Dec. 1933, 500, 522.

"A film featuring the staff, equipment, and key activities involved in the process of developing and printing Selo film at a laboratory. The viewer is guided through the different stages of the process with a step-by-step visual demonstration by Selo staff, accompanied by intertitles, providing information, and separating the scenes. The entire administrative and technical process is recorded, from the moment the used film stock arrives at the factory, continuing with the preparations made in the darkroom, before the chemical processes of developing, fixing, and washing takes place in the laboratory. The specific tasks of drying and measuring using industry-standard equipment, operated by hand, are next. In the printing laboratory, the negative is inspected and a Schustek 16mm printer is used. Intertitles explain the technical process of adjusting the light intensity when printing the film. In the spooling room, the printed positives are examined, and leader is cement spliced to the film. Title cards are produced. The completed film is projected and viewed. Each developed positive and negative film is skillfully wrapped, placed in a film can, packaged together into a Selo box and sealed, ready to be dispatched to the customer. A shot of many Selo Film boxes showing address labels completes the film" (EAFA Database).

Total Pages: 8